When it comes to embarking on a construction project that involves the use of Wood Plastic Composite (WPC) materials, selecting the right supplier is paramount.

The supplier you choose can significantly impact the success and quality of your project.

This article aims to highlight the key factors to consider when choosing a WPC supplier to ensure that you make an informed decision and secure a reliable partner for your construction needs.

I. Quality and Manufacturing Standards

Evaluate the Manufacturer The first step in selecting a WPC supplier is to assess the manufacturer behind the products.

Look for manufacturers with a proven track record and expertise in producing high-quality WPC materials.

Verify their manufacturing standards, certifications, and quality control processes to ensure that the supplier can provide materials that meet your project requirements.

Visit the Factory Where possible, arrange a visit to the manufacturer’s factory.

This allows you to see their production process firsthand and assess the quality of their facilities and equipment.

A well-maintained factory indicates a commitment to producing superior WPC products.

II. Product Range and Customization Options

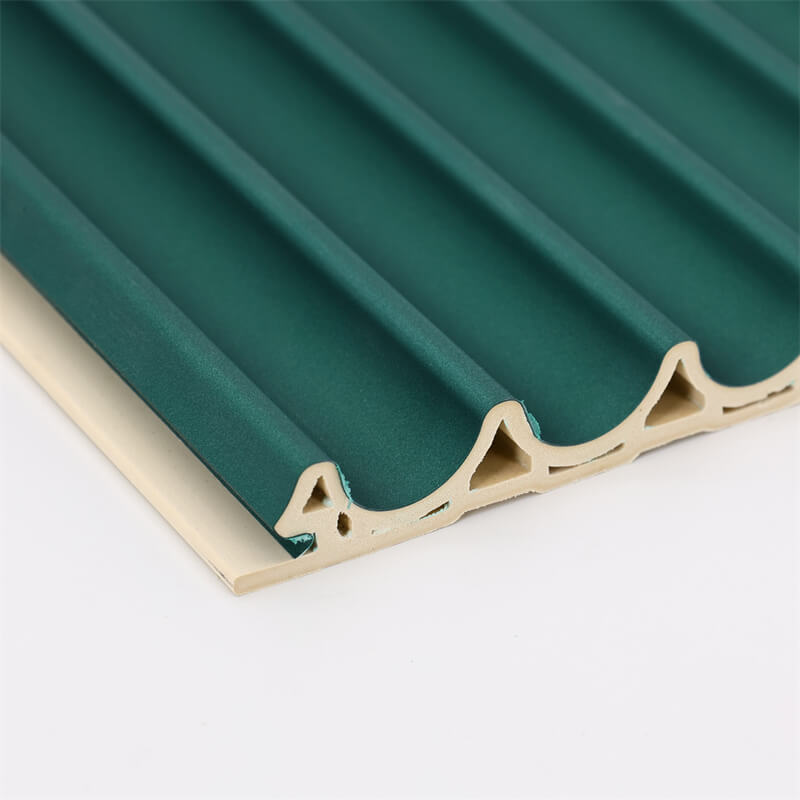

Diverse Product Portfolio Consider the range of WPC products offered by the supplier.

A reliable supplier should provide a comprehensive selection of WPC materials, including decking, cladding, railing, and more.

This ensures that you have access to all the necessary components for your project from a single source.

Customization Capabilities Every construction project is unique, and having the ability to customize WPC materials to suit specific design and functional requirements can be advantageous.

Choose a supplier who offers customization options in terms of colors, sizes, finishes, and textures, enabling you to achieve the desired aesthetic and performance goals.

III. Price and Cost-Effectiveness

Competitive Pricing While cost should not be the sole determining factor, it is essential to consider the pricing offered by the WPC supplier.

Compare prices from multiple suppliers, keeping in mind that the lowest price does not always guarantee the best value.

Look for a supplier who offers competitive pricing without compromising on product quality and service.

Long-Term Cost Savings Evaluate the long-term cost-effectiveness of the WPC materials offered by the supplier.

Quality WPC materials are known for their durability, low maintenance requirements, and resistance to environmental factors.

Investing in high-quality materials upfront can result in significant cost savings over the lifespan of the project.

IV. Reputation and Customer Support

Supplier’s Reputation Research the supplier’s reputation within the industry and among previous customers.

Look for testimonials, reviews, and references to gain insights into their reliability, professionalism, and customer satisfaction levels.

A reputable supplier with a strong reputation is more likely to provide a positive experience.

Customer Support and After-Sales Service Consider the level of customer support provided by the supplier.

Do they offer technical assistance, installation guidance, or maintenance advice? A supplier who offers comprehensive customer support can be invaluable throughout your project and even beyond completion, ensuring that any issues or concerns are promptly addressed.

Choosing the right WPC supplier is a critical decision that can significantly impact the success of your construction project.

By considering factors such as quality and manufacturing standards, product range and customization options, pricing and cost-effectiveness, as well as reputation and customer support, you can make an informed choice.

Take the time to evaluate different suppliers, request samples, and ask pertinent questions to ensure that you partner with a reliable supplier who can deliver high-quality WPC materials, provide competitive pricing, and offer excellent customer support.

By doing so, you can lay the foundation for a successful and smooth construction journey.